Read before you buy /ATEX in dedusting/

Posted: 04.05.2021

This article provides guidelines on the important aspects that need to be taken into account when deciding on the purchase of a dedusting installation for combustible materials (e.g. sawdust or paper dust), which create potentially explosive atmospheres. Such dedusting systems need to be designed and produced in accordance with the provisions of the binding regulations especially those which deal with the issue of ATEX.

The ATEX name derives from the first letters of French phrase: ‘ATmospheres EXplosives’ meaning explosive atmospheres.

Every year thousands of explosions caused by flammable substances such as gasses, dusts or liquids happen in various places all over the world. Explosions can cause enormous damages to the processing machines and factory buildings and they are a deadly hazard for the life and health of the people. That is why all countiers within the European Union have implemented regulations aiming at protecting people and places from such hazards. Today there are two main documents which have to be taken into account by producers and final users – these are ATEX Directives.

1. ATEX 153 Directive – for the users/employers also called ATEX Worker Protection Directive

The Directive 99/92/EC of the European Parliament and of the Council of 16 December, 1999 on minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres.

The above mentioned directive was implemented into Polish legislation by the Regulation of the Ministry of Economy of 8 July 2010 on minimum requirements for health and safety associated with the risk of the explosive atmosphere occurrence in workplace (Dz. U. Nr 138, poz. 931).

2. ATEX 114 Directive – for producers

The Directive 2014/34/EU of the European Parliament and of the Council of 26 February, 2014 on the harmonisation of the laws of the Member States relating to equipment and protective systems intended for use in potentially explosive atmospheres, which applies to the following:

a) equipment and protective systems intended for use in potentially explosive atmospheres;

b) safety devices, controlling devices and regulating devices intended for use outside potentially explosive atmospheres but required for or contributing to the safe functioning of equipment and protective systems with respect to the risk of explosion;

c) components intended to be incorporated into equipment and protective systems referred to in point (a).

The directive was implemented into Polish legislation by the Regulation of the Ministry of Economy of 9 June 2016 on minimum requirements for protective devices and protective systems intended for use in potentially explosive atmpospheres (Dz.U. 2016 poz. 817).

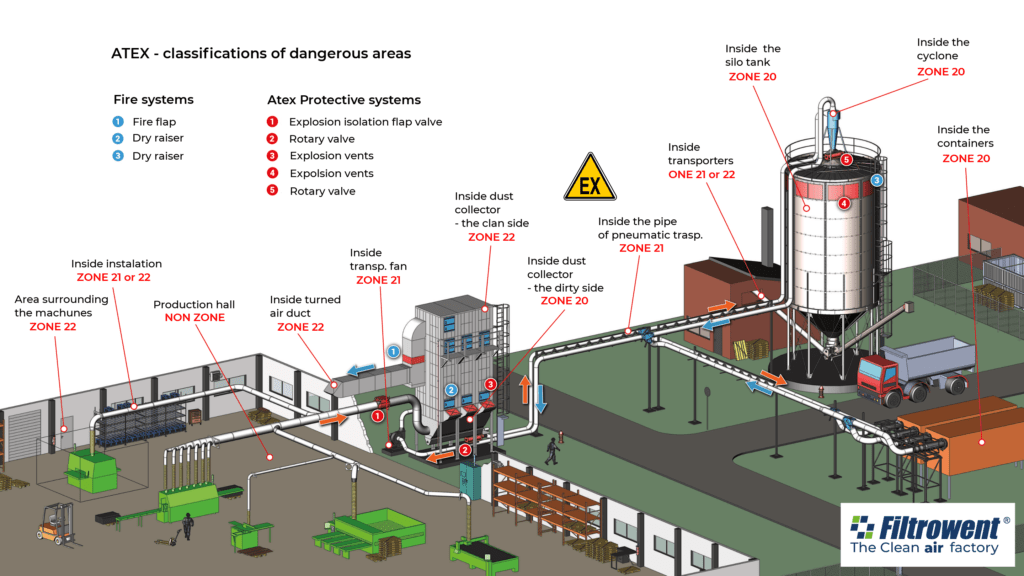

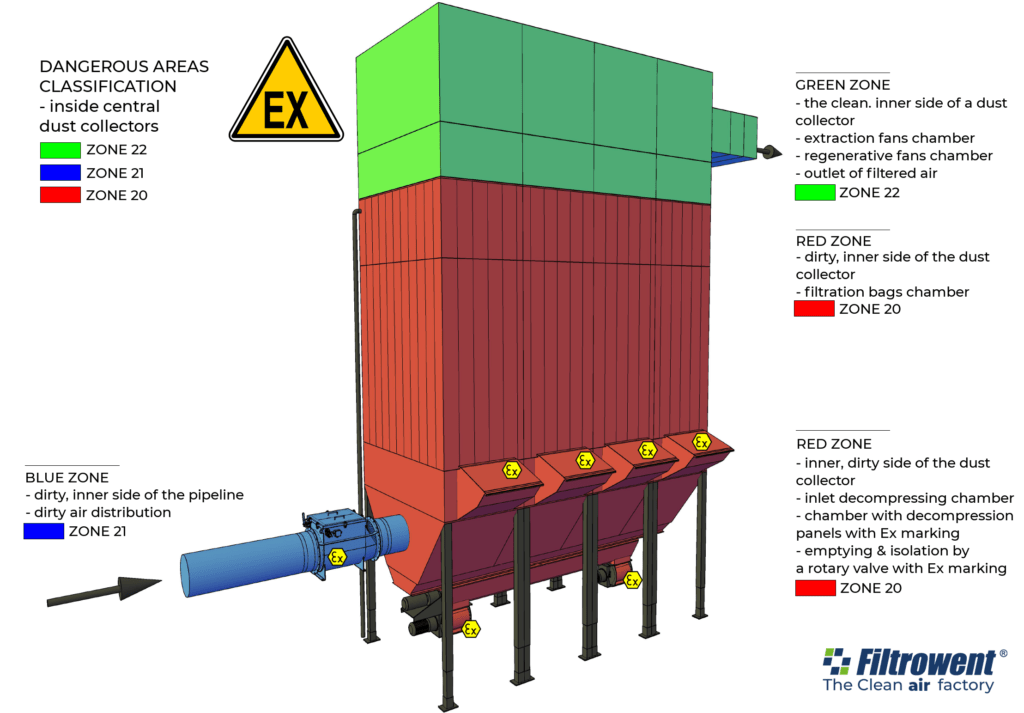

3. The applications of the ATEX directive in industrial dust collecting

An explosion risk zone is an area in which an explosive mixture of flammable substances with air or other oxidizing gases occur, of a concentration between the lower and upper explosive limit. The explosive risk areas are determined on the basis of the probability of and the duration of explosive atmosphere occurance and they are classified into the following zones:

Zone 20

It is a place where an explosive atmosphere in the form of a cloud of combustible dust in the air is present continuously, long or frequently.

Zone 21

It is a place where an explosive atmosphere in the form of a cloud of combustible dust in the air may occasionally occur during normal operation.

Zone 22

It is a place where an explosive atmosphere in the form of combustible dust in the air is not likely to occur in normal operation but, in case when it does occur, it persists for a short time only.

Note: when classifying explosion risk areas, all combustible dust layers, heaps and deposits have to be considered as any other ignition soruce that can cause explosion hazard area.

4. How should a dust collector be properly protected against the effects of explosion?

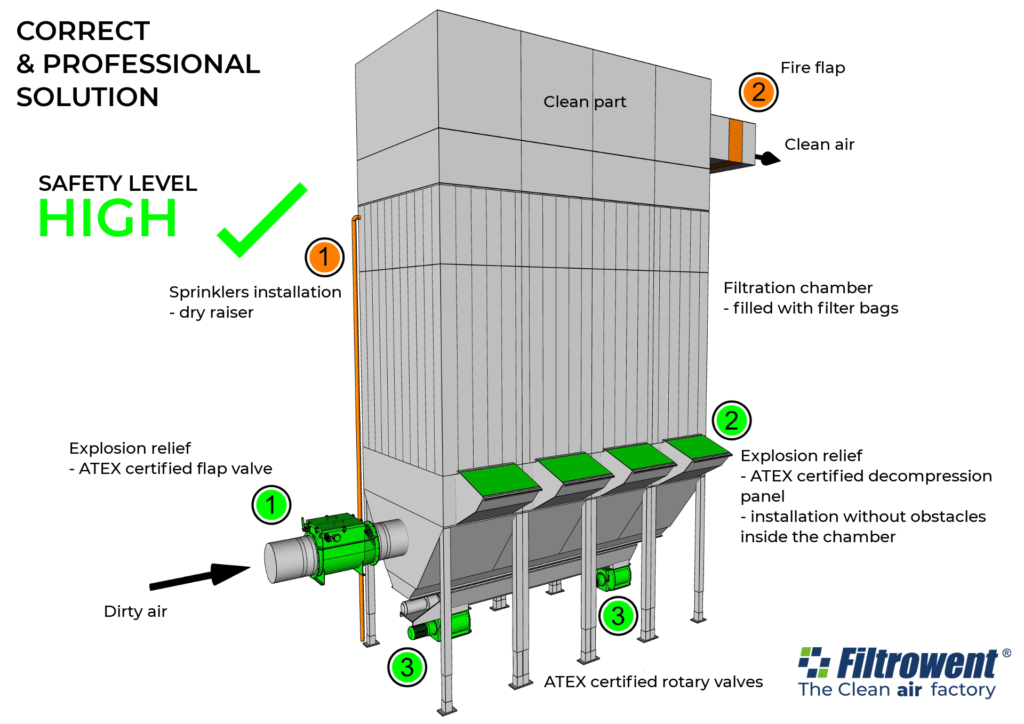

Before making a decision of which particular filtration device to buy, it is important to pay attention to the adequate protection of a dust collector against the consequences of an explosion. There are many various protective systems that are designated for dedusting systems working with materials of flammable and explosive properties. It is crucial that these devices are with the ATEX certificate. The dust collectors of the EKO-FILTR series produced by Filtrowent International are, as standard, designed to be equipped with individual protective systems, especially with:

a) explosion venting devices – explosion vents (decompression panels)

b) explosion isolation devices – flap valves and rotary valves

CORRECT AND PROFESSIONAL SOLUTION OF DUST COLLECTOR PROTECTION AGAINST EXPLOSION EFFECTS

WHY DOES THE ABOVE PRESENTED SOLUTION PROVIDE A HIGH LEVEL OF PROTECTION AGAINST FIRE AND EXPLOSION EFFECTS?

- On the crude air part of the filter there is a certified protection device installed – the flap valve, which, in case of explosion inside the dust collector, effectively isolates the dust collector from the other parts of the dedusting system such as inside of the buildings and the working places. This way the risk of life loss or health damage of the people working inside the buidling is minimized to great extend, together with the risk of property damage and loss.

- Certified explosion decompression panels (also called explosion vents) are installed on the dirty side of the dust collector, where no obstacles (such as filter bags) occur. The decompression chamber of the dust collector is an empty space and such location of the decompression panels enables them proper and effective reaction in case of explosion. This solution is also compliant with the PN-EN 14491.

- On the inlet of the dust collector (the bottom part of the device where dirty air comes in) a certified rotary valve is installed, which in case of explosion, effectively isolates the dust collector and this way prevents the explosion from spreading into other parts of the system. The use of a certified rotary valve is the same as of a certified flap valve – both devices are installed on the dirty side of the dust collector (see p. 1).

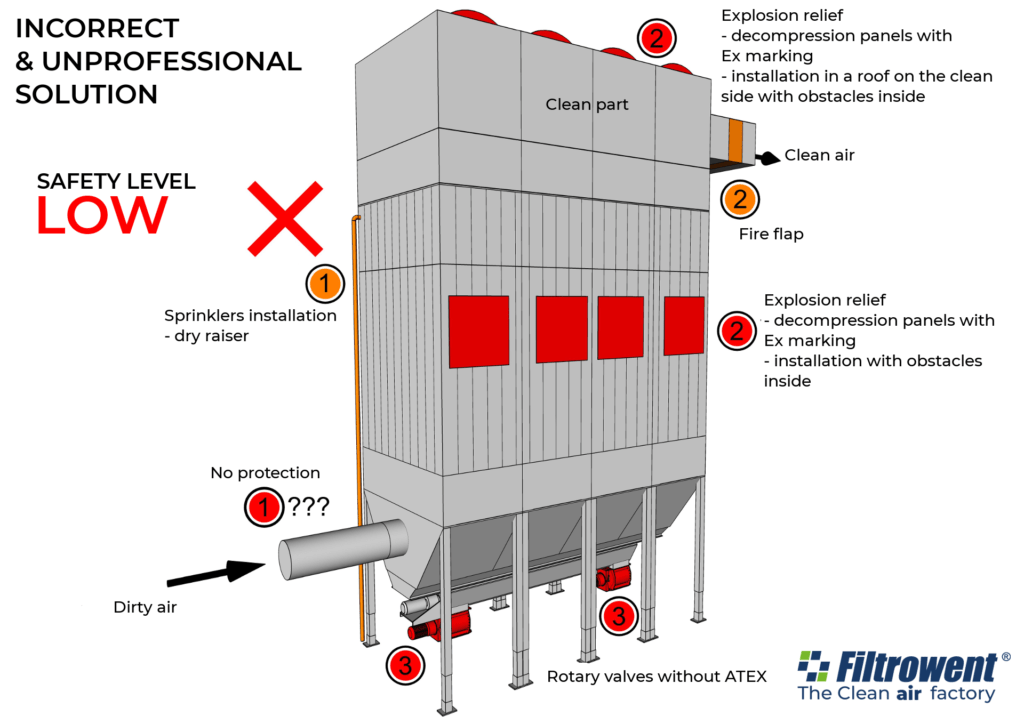

INCORRECT AND UNPROFESSIONAL SOLUTION OF DUST COLLECTOR PROTECTION AGAINST EXPLOSION

WHY IS THE ABOVE PRESENTED SOLUTION INCORRECT AND DANGEROUS, BUT STILL OFTEN USED?

1. There is not any explosion isolating device on the dirty air inlet. In case of explosion, the explosion will spread on the other parts of the system, causing much greater risk of life and health loss for the people and a risk of serious damages for the buildings and machines.

2. Filter bags are mounted on the same level as decompression panels which disables the panels to work properly and vent the explosion out of the device in a controlled manner. Lack of proper explosion venting of a dust collector may cause serious damage of the device: the explosion that is not relieved destroys the dust collector by tearing it apart, in effect lots of sharp metal parts are thrown out in uncontrollable manner causing deadly danger for everyone in the area. What is more, the buildings in the direct vincinity of the dust collector are also damaged and at risk of catching fire causing even more danger.

3. On the outlet of the dust collector, in its lower part, the rotary valve is without ATEX certificate. Which means, that in practice, explosion will spread from the dust collector to other parts of the system causing further danger for people and damages to the buildings and other facilities.

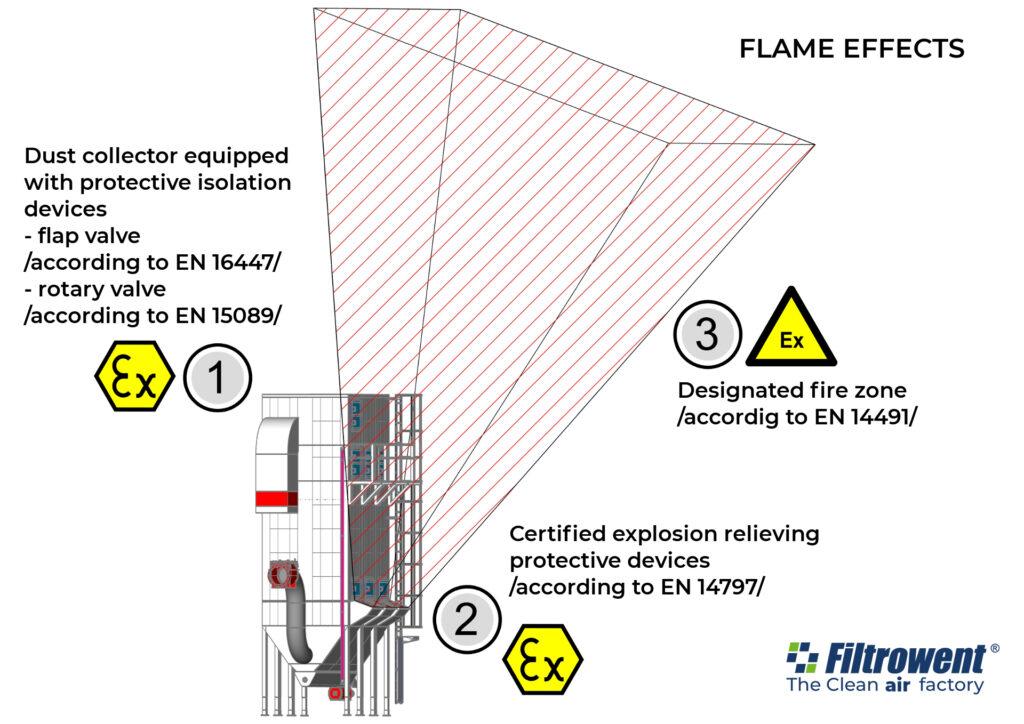

5. Flame propagation effects outside the venting

Explosion that is vented throws out the burnt and not burnt material together with flames outside – into the venting area. Because of this, certain safety measures have to be employed to protect people as well as the neighbouring installations and buildings. The area into which the explosion is directed should be without access for people and at appropriate distance from other buildings and installations in order to avoid additional fire and explosion.