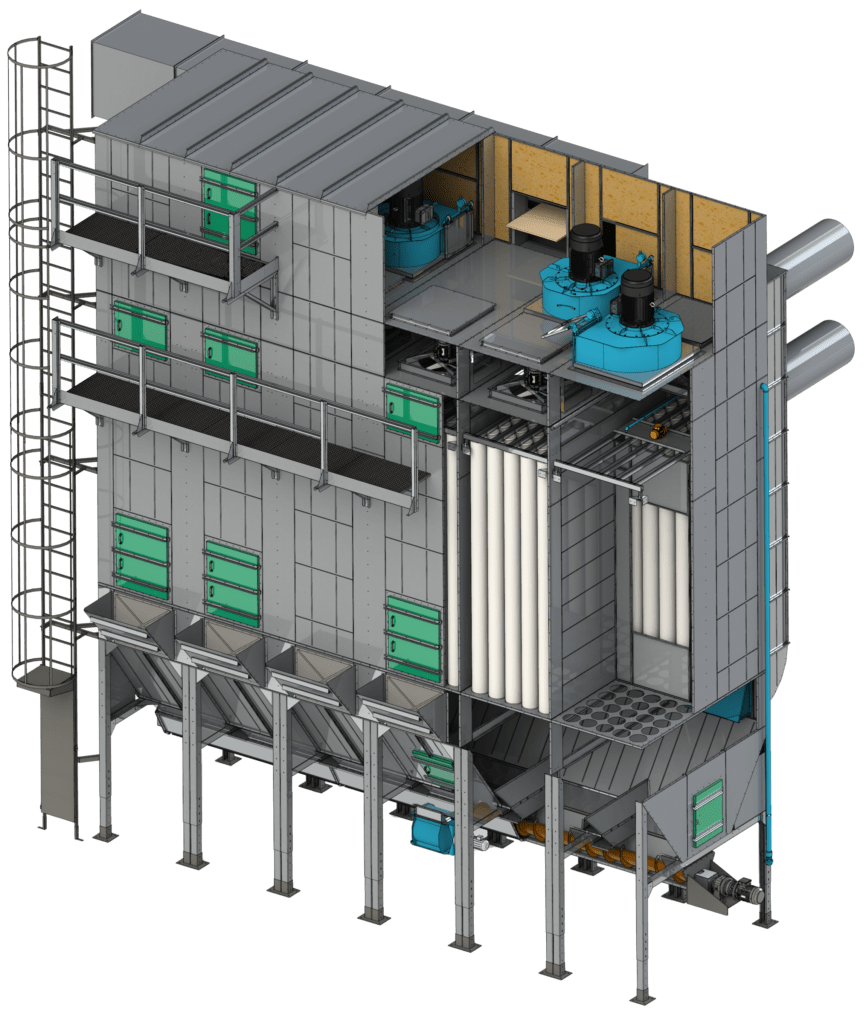

ODP bag dust collectors

ODP dust collectors are designed to work outdoors but in certain cases they can also be located indoors. ODP can work in overpressure and negative pressure systems. The device is used for dust extraction and filtration in various industries such as: wood processing, furniture production, paper production, recycling and plastics processing.

In ODP dust collectors the dust is sucked inside the filter bags, which are open at the bottom and mounted to the plate with the use of snap-rings. This method makes the replacement of the filter bags much easier.

Cleaning of filter bags is with the use of regenerative fans mounted directly above the filter bags. Each ODP module is equipped with one or two regenerative fans. Cleaning takes place during the operation of the dust collector, modules are cleaned one after another.

ODP module sizes:

- single 1360 x 1360 mm

- double 2720 x 1360 mm

Both types of modules can be connected with one another, this way the filter can be expanded by adding twin-like modules. This solution allows to increase filter efficiency.

Available emptying methods of ODP dust collectors:

- ODP-K – directly into bins or a big bag (higher legs of dust collector)

- ODP-S – with a rotary valve installed beneath the hopper – enables dosing and further transport of the dedusted waste

- ODP-TSO – with a screw conveyor equipped with an opening for the rotary valve

ODP dust collectors, can be equipped with different size of filter bags: S, M, L and XL to fit the required airflow demand. The ODP dust collectors can be extended by adding new modules in time.

ODP dust collectrs are produced in accordance with the ATEX directive and are suitable for St1 explosivity class dusts.