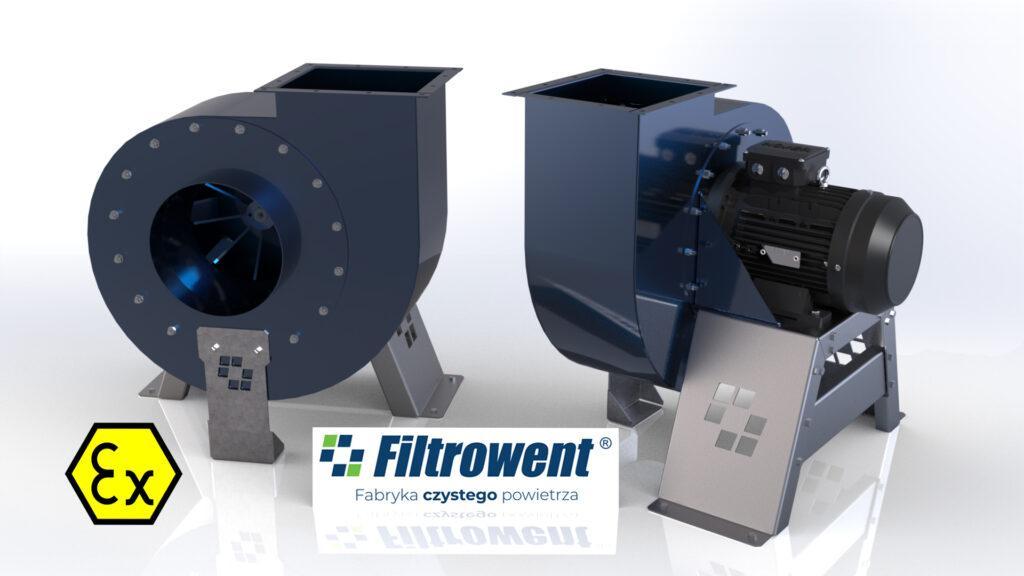

Exhaust fans with ‘Ex’ marking

Our radial conveying fans are used for pneumatic transport of chips, sawdusts and other dusts, which are produced during processing of various materials.

General characteristics and use of fans

Depending on the fan size, its casing can be produced of steel sheets from 2 mm up to 5 mm thickness. The fans can be equipped with an open self-cleaning rotor, which – again, depending on the fan size – is produced of steel sheets from 3 mm to 5 mm thickness. Fans are indispensible components of dust collectors for conveying different mixtures of air with waste material such as chips, sawdusts and other post processing dusts.

In order to meet the requirements of the ATEX directive, the standard versions of our FiltroFan fans are equipped with:

- copper ring located on the dirty side of the air inlet

- inspection door on the fan casing

- evening-up connective elements between the bolted parts

- electric motor designed to work in explosive atmosphere

Basic parameters of the FiltroFan conveying fans

| Type of fan | ATEX equpiment | Efficiency |

|---|---|---|

| WTD/225-EX 2,2 kW | – open and self-cleaning rotor – copper ring on the air inlet – compensatory connections – motor with Ex marking – inspection door | 1500 m3/h at 202 mmH2O 3500 m3/h at 112 mmH2O |

| WTD/250-EX 4,0 kW | – open and self-cleaning rotor – copper ring on the air inlet – compensatory connections – motor with Ex marking – inspection door | 2500 m3/h at 253 mmH2O 5500 m3/h at 115 mmH2O |

| WTD/275-EX 7,5 kW | – open and self-cleaning rotor – copper ring on the air inlet – compensatory connections – motor with Ex marking – inspection door | 3500 m3/h at 325 mmH2O 8000 m3/h at 129 mmH2O |