Rotary valves – ATEX protective system

Rotary valves are used to discharge bulk materials such as wood shavings, dust etc. from cyclones or bag dust collectors. Rotary valves of FZC type are of modular structure and are available in different lengths and of different capacities.

The seven-blade rotor is welded and reinforced with ribs making the valve a truly heavy-duty device. The rotor blades are equipped with highly-resistant rubber, ensuring effcient airlock between the inlet and outlet. The body of the valve is made of heavy gauge mild steel.

The main function of rotary valves is to prevent the air pressure loss (air leakage) and to simultaneously convey material from one device to another, for example from a dust collector to pneumatic transport system.

Our rotary valves comply with the essential provisions of the Directive 2014/34/EU of the European Parliament and of the Council of 26th February 2014 on the harmonisation of the laws of the Member States relating to equipment and protective systems intended for use in potentially explosive atmospheres.

Our FZC STD rotary valves work as explosion isolation system and are devices certified by a notified body (No.: 1453, GIG, Mikołów, Poland).

Valves are produced with the following marking:

St2 II 1/-D Ex h IIIB T125stC Da/-

St2 II 1/2D Ex h IIIB T125stC Da/Db

St2 II 1/3D Ex h IIIB T125stC Da/Dc

St2 II 2/-D Ex h IIIB T100stC Db/-

St2 II 2D Ex h IIIB T125stC Db

St2 II 2/3D Ex h IIIB T125stC Db/Dc

Basic technical data:

version for explosive dust of the following class:

– St1 i St2 (Kst max 300 [m bar/s])

endurance/ reduced explosion pressure:

– pred ≤ 50 kPa

EU Type Testing certificate

ATEX-Q certificate on quality assurance

The production process of our rotary valves is controlled and inspected by a notified body No 1453 – the Central Mining Institute (GIG) and we received the certificate on quality assurance No: GIG22ATEXQ117.

Location of the rotary valves:

– between the filter and the silo

– between a cyclone and a silo

– between a filter and a container

– between a cyclone and a container

– between a filter and a pneumatic transport installation

– between a cyclone and pneumatic transport

Advantages:

- up to three times higher efficiency when compared to the valves available on the market

- long and failure free life of the device

- 6 mm thick rubber blades made of abrasive-resistant, high-grade styrene-butadiene rubber – SBR), additionally reinforced with linien

- wider discharge opening – 350 mm

- 7-blade rotor produced in welding technology and reinforced with the use of additional bulkhead connectors – wider discharge chambers between the blades are obtained

- chain clutch – higher stability

- equipped with a NORD cylindrical motoreducer as standard

- equipped with a protective casing for the motroreducer as standard

- mild start-up at valve working initiation

- easy maintenance including demounting of the motoreducer and replacement of rubber blades

- modular structure enables extension

- spare parts availibility from the warehouse in Poland

| Rotary valve type | Rotation speed [rot/min] | Motor power [kW] | Maximal theoretical efficiency [m3/h] | Efficiency at 50% load [m3/h] | Approximate weight of a rotary valve with a motoreducer [kg] |

|---|---|---|---|---|---|

| FZC-500-7-STD/EX | 21 | 0,75 or 1,1 | 103 | 52 | 130 |

| FZC-750-7-STD/EX | 21 | 0,75 or 1,1 | 155 | 78 | 185 |

| FZC-1000-7-STD/EX | 21 | 1,1; 1,5 or 2,2 | 207 | 103 | 225 |

| FZC-2000-7-STD/EX | 21 | 1,1; 1,5 or 2,2 | 414 | 206 | 420 |

| FZC-3000-7-STD/EX | 21 | 1,1; 1,5 or 2,2 | 621 | 309 | 600 |

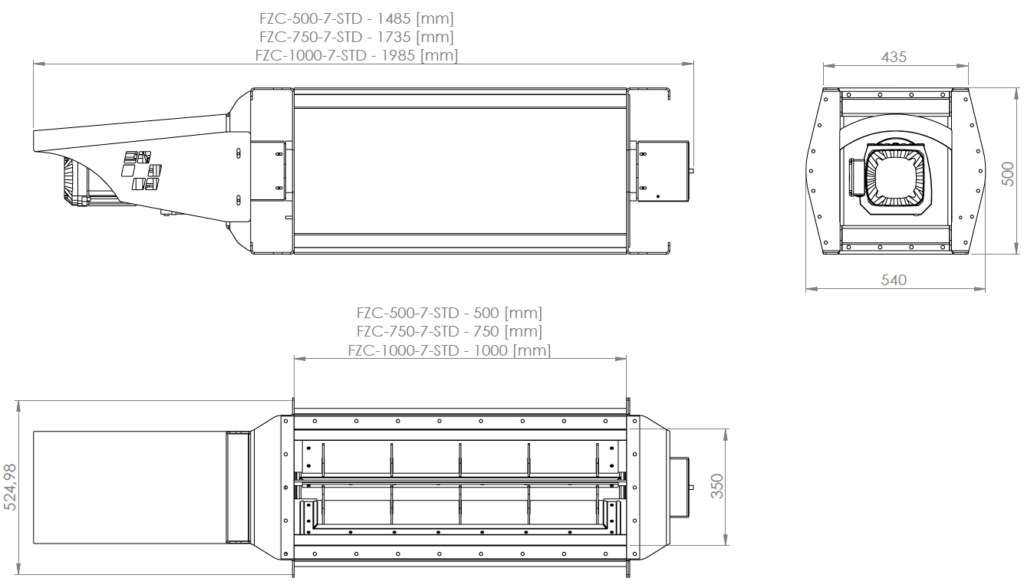

Basic dimensions:

Basic module dimensions, rotary valve types 500, 750 and 1000.

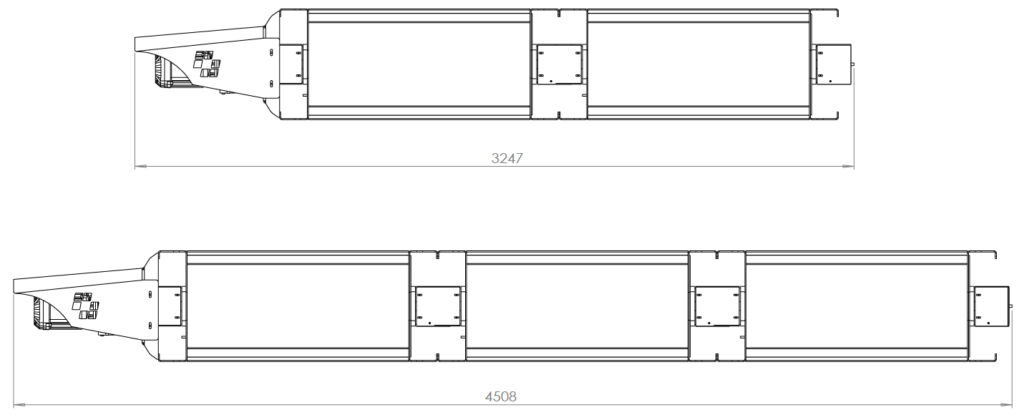

Extended valve module, rotary valve type 2000 and 3000.