Dust extraction system at FILJAN

Posted: 13.03.2024

A case study of recently assembled and commisioned dust extraction system for wood processing company

FILJAN, a company founded in 2014, has become a leader in designing and constructing wooden houses produced in timber frame technology. With many completed projects and happy customers whose dreams of their own house that is environmentally friendly, comfortable and energy-efficient, have come true, the company has secured its strong and recognizable brand on the market.

Customers looking for their dream house may choose a ready design from a wide range of house projects provided by FILJAN or decide on an individually designed house that will include customers’ desired features and individual needs. The company ensures impressive pace of house construction – it takes only one to four weeks to complete a house from foundation laying to a tenant build-out state.

Production of prefabricated timber houses involves advanced technology which in vast part takes place in a factory. This reduces the work on-site allowing faster construction works independently to the weathering conditions and ensures dimensional precision of the construction elements to a level incomparable with the traditional house construction on site.

The founder of FILJAN, Karol Mazur, has ambitious plans for further development of the company. Part of these plans included safe and dust-free working environment in his factory. This meant providing a bespoke, turn-key extraction system which would require minimum operation as well as ensure easy disposal of the extracted wood waste.

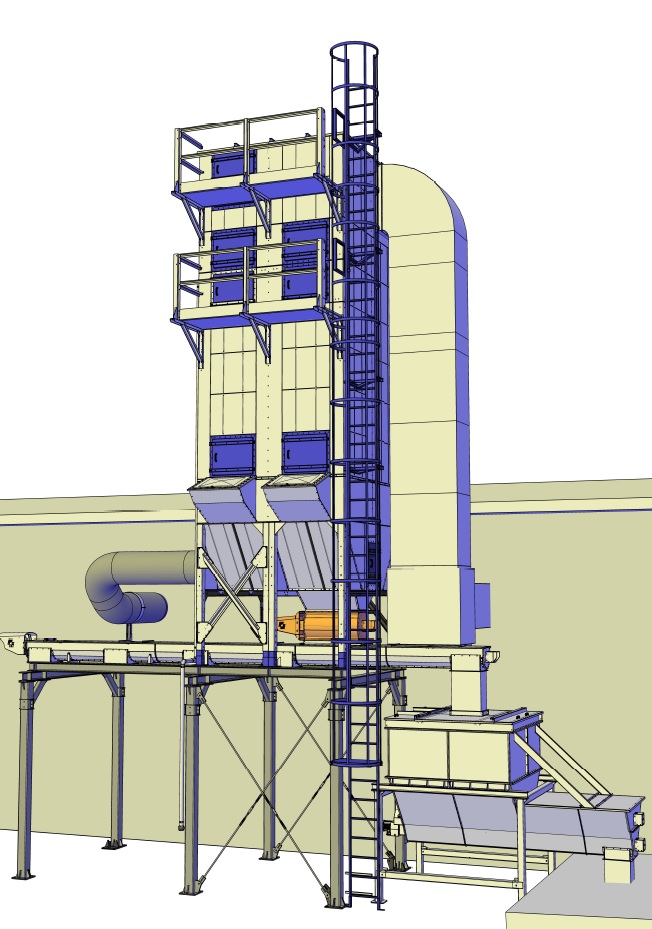

The newly assembled extraction system is fully ATEX compliant and it consists of:

- an ODP-2SL bag house dust collector (air efficiency 25 000 m3/h) with regenerative fans bag cleaning system

- an FZC-1000 rotary valve which delivers waste to a screw conveyor and works as ATEX explosion isolation system preventing potential explosion from spreading

- an FTS-UO-250 screw conveyor which fills the container evenly with the waste

- extraction fan (equipped with an inverter) located in the top part of the dust collector enabling energy saving operation

- an UBD-1W buffer tank (8 m3 capacity) for feeding the heating room and waste storage in case when the main container is full/ or being emptied.

At Filtrowent International we are happy to have provided yet another tailored made solution of safe and efficient dust extraction. We believe it will add to the general development of FILIAN company in the future.

www.filjan.pl